Plastic has always been used as an insulating material because of its high insulation. However, as electromagnetic interference (EMI) shielding, microwave absorption and other technologies have attracted more and more attention, related application fields have put forward electrical conductivity requirements for plastics. In the past ten years, countries all over the world have carried out extensive research on it, and strive to introduce a new generation of plastic materials, which will not only maintain the inherent advantages of plastics but also impart new conductive properties.

(1) Definition of conductive plastic

Conductive plastic is a functional polymer material that mixes resin and conductive material and processes it using traditional plastic processing methods.

(2) Classification of conductive plastics

Conductive plastics are divided into two categories. Conductive plastics made by physical methods are called composite conductive plastics, and conductive plastics made by chemical methods are called intrinsic (also called structural) conductive plastics.

|

product |

classification |

Subdivision |

The main purpose |

|

Electromagnetic shielding plastic |

Compound 1 |

Filling type: filled with metal powders such as copper and nickel, stainless steel fiber, carbon fiber, copper fiber, nickel-plated carbon fiber, etc. |

Electromagnetic shielding Antistatic |

|

Intrinsic type |

Synthetic type: Intrinsic conductive polymer (ICPS) of conjugated π-electron system such as polyaniline, polyacetylene, polypyrrole, etc. |

1 Note: Currently 90% of conductive plastics are composite type

(1) Intrinsic conductive plastics refer to plastics in which the polymer itself has conductivity or is chemically modified. They can play the role of their own chemical structure, making them essentially conductive, and then chemically doped to increase their conductivity. For example, the conductivity of doped polyacetylene is 4 times that of copper, which is currently the most conductive material at room temperature. The advantage is that the conductivity is uniform in the entire material, and the conductive state is easily controlled quickly; the disadvantage is that the cost is expensive, the processing is difficult, and the chemical stability is poor, so the application field is limited. Intrinsic conductive plastics are mainly used as electrodes and solid electrolyte materials for various secondary batteries to take advantage of their light weight, high energy density, and good voltage characteristics.

(2) Composite conductive plastics refer to plastics with electrical conductivity after physical modification. Generally, conductive materials such as carbon black, carbon fiber, graphite, metal powder, metal fiber, etc. are blended into resin. At present, the technology is very mature and the application is also very extensive.

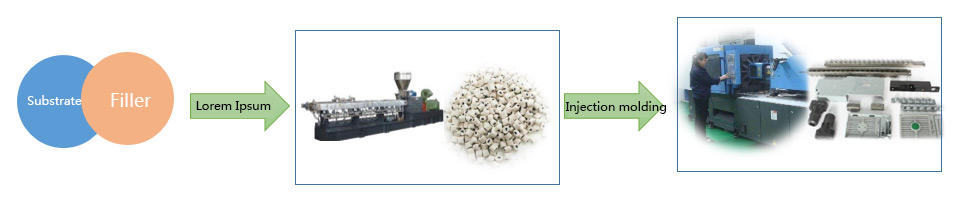

(3) Conductive plastic production process (take Fei Rongda as an example)

(3) Partial application of conductive plastic

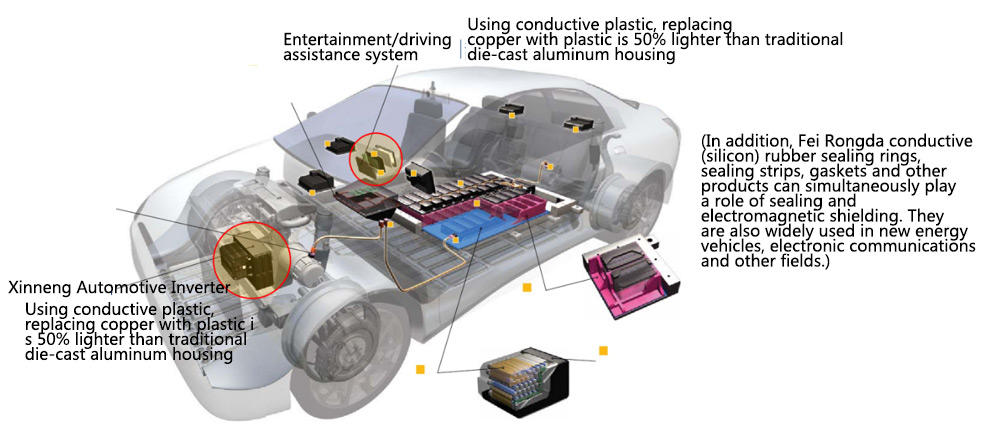

In theory, most of the known plastics can be used as the base material of conductive plastics, and there are many suitable conductive fillers. Conductive plastics can maintain the inherent characteristics of plastics and have similar metal conductivity characteristics. It can now be applied to almost every new industry, especially in the manufacture of optical communication semiconductors, superconducting materials, integrated circuits, automotive electronics, electrical And other fields will occupy a very important position.

Currently, conductive plastics, self-limiting temperature heating materials, antistatic materials, electromagnetic shielding materials, conductive films and other products have been widely used. With the gradual deepening of theoretical research in the field of conductive plastics, conductive plastic products continue to introduce new ones, and their performance continues to reach new highs, and their application scope is constantly being developed and expanded. This article mainly introduces the application of conductive plastics from the following aspects.

(1) Antistatic

The insulation of plastics causes the static charge accumulated on the surface of the plastic product to be unable to be released, and then forms a static voltage, which is easy to attract dust and other dirt. After the static voltage reaches a certain level, electrostatic discharge and electric shock will occur. In the electronics industry, various precision instruments and precision electronic components will be damaged or even scrapped due to electrostatic breakdown. In addition, in some industrial and mining enterprises that come into contact with flammable and explosive materials, if electrostatic discharge is not effectively protected, it will produce More serious consequences and cause major economic losses. For example, the accumulation of static electricity in plastic gas pipes in coal mines can cause coal mine explosions; the plastic parts in oil tankers cause oil fires and fires due to static electricity; accidents often occur due to static electricity during the production of plastic films. Therefore, the shells and structural parts of electrical products used in coal mines, oil tankers, oil fields, dust and combustible gases have anti-static requirements.

(2) Electromagnetic shielding

EMI shielding shells for electrical products in the fields of communications, computers, automation systems, industrial electronics, consumer electronics, and automotive electronics, as well as semi-conductive shielding materials used in medium and high voltage cables.

(3) Conductive grounding

Carbon fiber conductive plastic is used as a comprehensive penetrating ground wire protective sheath material to replace the original lead sheath and used for the grounding requirements of railway transportation. It has high strength and modulus, low resistivity, excellent electrical conductivity, good electromagnetic shielding effect, good corrosion resistance, no pollution to soil and groundwater, and good environmental protection.

(4) Prospects for conductive plastics

With the rapid development of high and new technology, the application range of conductive plastics continues to expand. In addition to commonly used fields, conductive plastics have important prospects in the fields of solar cells, plastic chips, display devices, nanowires, robotics and life sciences.

Conductive plastic potentiometer--Since the main material of the conductive plastic potentiometer is plastic and carbon powder, it is made by molding. Compared with the traditional wirewound potentiometer, it has smooth output, fast response, wear resistance and long service life, and friction torque Small and other characteristics. In addition, the improvement of key technologies such as preparation and linear repair of resistors has laid a solid foundation for the high-precision and large-scale production of plastic potentiometers.

Plastic solar cells-also referred to as organic cells, use polymers instead of silicon to convert sunlight into electricity, which can reduce the cost and weight of solar cells and make them soft, but the conversion efficiency of plastic solar cells is only about 10% (Lower than the efficiency of commercial silicon solar cells between 15%-20%). At present, the conversion efficiency has been improved by adding solvents. In 2018, Nankai University, China, the team of Professor Chen Yongsheng designed and prepared laminated organic solar cell materials and devices with high efficiency and wide-spectrum absorption characteristics, achieving a photoelectric conversion efficiency of 17.3%, which once again refreshed the organic/polymer solar energy reported in the literature. The world record of battery photoelectric conversion efficiency.

Plastic chips--As early as 2016, a team of foreign scientists transplanted high-performance magnetic memory chips onto a flexible plastic surface without compromising its performance. The resulting transparent film-like flexible "smart plastic" chips have excellent data storage and processing capabilities , Is the first plastic flexible magnetic memory chip.

Display devices, such as light-emitting diodes made of high-molecular polymers, have been used in many mobile phone monochrome displays and other display devices. Pioneer of Japan has developed a new type of light-emitting display based on the electroluminescence principle of conductive plastic. The application of this conductive plastic improves the switching speed between pictures on the display. In addition, conductive plastic has excellent plasticity. Through this, some special devices can be manufactured, such as foldable or curved TV screens.

Nanowires-conductive polymer materials prepared by nanotechnology, with fine structure and good conductivity, which can be used in molecular circuits, molecular wires and some molecular-level components.

Robots and life sciences-Japanese scientists have discovered that conductive plastics can make artificial skin and artificial muscles. This skin can be used on robots to make the robot muscles more elastic. This is controlled by electrochemical methods. Conductive plastic artificial muscle, it can contract and expand, almost comparable to real muscles. In addition, scientists have found that the human body also has a certain degree of conductivity, so if conductive plastics are combined, it can help modify DNA. Given the importance of research in the life sciences, it may be the most important trend in the application of conductive plastics.

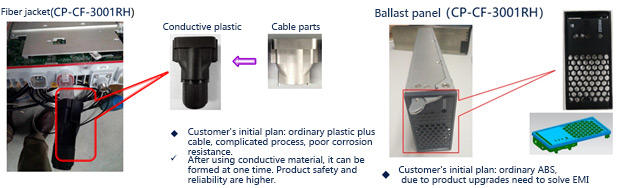

(5) Advantages of Fei Rongda

Fei Rongda is one of the earliest scientific and technological innovation companies in China to develop and produce modified plastics. It has carried out "school-enterprise cooperation" with Tianjin University to make full use of the academic advantages of universities and build a platform for technological innovation and achievement transformation, so that Fei Rongda The research and development capabilities of modified plastics have reached a new level. Today, Fei Rongda can provide complete modified plastic thermal and electrical conductivity solutions (including raw materials, mold design, injection molding, etc.) to meet the application needs of related industries.